ESA funding approved for manufacture of XCAM’s world first particle contamination monitor for space flight

20/03/2023

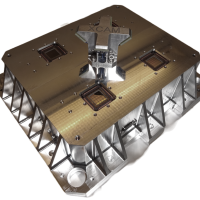

Following an 8-year technical development programme in collaboration with the European Space Agency (ESA), UK based XCAM Ltd, leaders in specialist digital camera systems, are delighted to announce significant further funding from ESA for the manufacture of its Space Particle Fall Out (PFO) Monitor. Due to be ready to launch into space inside a rocket launch vehicle fairing in the summer of 2025 the Space PFO will be the first instrument to measure particulate contamination inside a rocket fairing during, and shortly after launch.

Launch vehicles and their enclosed satellite payloads experience significant degrees of mechanical and acoustic shock and vibration during their short journey into space. Nothing is currently known about the sources and types of particulate contamination inside a rocket fairing during launch, however, it is certain that contamination can seriously affect the performance, accuracy and reliability of the multi-million dollar instruments which are routinely sent into space to study our planet and explore the universe.

Karen Holland, CEO of XCAM Ltd, explained, “We are grateful to ESA for their continued support over the last 8 years in the development, manufacturing and testing of prototypes, of this unique instrument. This next tranche of funding takes us to our final launch goal and we are delighted that ESA have the confidence that XCAM can continue to lead the way on these difficult and complex technology development programmes and deliver to their exacting quality standards.”

The Space PFO Monitor is a complex instrument that provides a remote, automated, real-time method of detecting particulate contamination down to the five-micron level in a rocket fairing during and shortly after launch, and will provide valuable data to demonstrate whether or not precious cargos, such as Earth-observing satellites, stay clean on their way into space. It is designed to withstand the varying vibration, shock, acoustic, pressure, temperature and humidity environments experienced during launch and can be deployed across a wide range of different launch vehicle families.

“Up to now, the cleanliness levels of ESA missions are carefully controlled during assembly, integration and testing, especially for sensitive payloads like those of Science and Earth monitoring. However, what happens to the satellites in the last days on Earth and once they are on their way to orbit remains a mystery. We are looking forward to having a technology game changer in the field of cleanliness and contamination control that will allow us to monitor, and hopefully improve, the particulate contamination levels during launch" says Riccardo Rampini, head of Materials' Physics and Chemistry section in ESA/ESTEC and technical officer of this activity.

Following the success developing the space system prototypes, XCAM has also adapted the PFO technology for commercial use, and distributes the PFO 1040 real-time surface particulate contamination monitoring system to cleanrooms and clean assembly plants worldwide. A great example of the spin-out of space-derived technology to the wider world.

Award-winning XCAM, designs and manufactures highly specialized custom and low-volume complex digital camera systems for challenging scientific, environmental and space applications. They are one of only a few companies in the world to offer complete bespoke imaging sensor camera solutions. XCAM have a worldwide reputation for their ability, reputation, expertise, and outstanding knowledge in the field.

Find out more here: Space PFO